Status is an annual or monthly recurring event that can be quite challenging. It's never entirely easy, but with this guide in hand and the videos below, the status process should become significantly easier to navigate, with the aim of achieving the most accurate results possible.

Status in Bikedesk/Customers 1st is done within the system and can be carried out using a cash register computer. However, we recommend using a laptop computer with a connected barcode scanner, so employees can move around with it. It's possible to have multiple people working simultaneously, so you can use your phone while others use a laptop and a barcode scanner.

You can search for products individually either by SKU or barcode (not recommended)

You can either use a handheld barcode scanner (gun) that is directly connected to your computer via USB - these can be either wired or wireless (prefered)

You can use your smartphone/tablets camara as barcode scanner (slower)

You can import scanlists (from external scanners) directly into the status-module as a CSV-file.

It's important to thoroughly read the guide (preferably multiple times) before embarking on the big annual project. Also, make sure to read the frequently asked questions and answers at the end of the guide. Yes, there is a lot to go through, but it's necessary to ensure that you have complete control over the inventory of your business.

We have divided the guide into three main sections and created videos for each section so you can jump ahead based on where you are in the status process.

Preparation

During status

Completion of status

These are the three sections we will go through in the guide. Please note that the guide may not cover every possible way to conduct status since there can be different methods. This is simply the easiest approach in our system.

The text version of the guide is quite lengthy because inventory, regardless of the system, is an important process with many details. We have created three videos to help you with this.

Making inventory may sound simple - you just need to count everything and adjust the inventory. But to achieve the best possible result, we recommend a series of preparations before starting the inventory process, so the actual counting and adjustment are as easy as possible.

In the video above, we have covered the following key points for preparation:

Video is currently only availible in Danish.

What items should be included in the inventory, and when?

In our system, there are different ways to perform inventory:

Entire inventory

Items with a serial number

Specific product categories

It's important to decide from the beginning as it determines how the inventory will be completed and how the rest of the preparation looks.

It is possible to spread the inventory over several days in the system, but we strongly recommend completing the inventory as quickly as possible to reduce the risk of errors and make error tracking much easier when it comes to finalizing the inventory.

It's important that the store is physically well-prepared for a successful inventory.

Clean up the store so that the items are in their correct places.

Ensure that all items have barcodes. If there are items without barcodes, create functional ones to expedite the counting and scanning process.

Divide the store into an appropriate number of areas - we recommend as many areas as possible. This greatly helps with error tracking, as you can see exactly on which list a specific item has been counted.

Assign responsibility for inventory - who counts which areas?

Ensure that one employee is responsible for reviewing items with differences once the inventory is underway.

Prepare an Excel sheet with the inventory lists so that the staff can check off items as they progress.

If you find an item on the wrong shelf, count it in the area you are in and reorganize when the inventory is completed.

Do not start a new area until you have finished.

Do not start a new area until you have confirmed that the computer area has changed.

The actual process during inventory is relatively simple. Count the products, verify the quantities, and you're done.

In theory, at least. In practice, there is a bit more to keep track of, but if multiple people have devices to count, it can be completed relatively quickly.

Video is currently only availible in Danish.

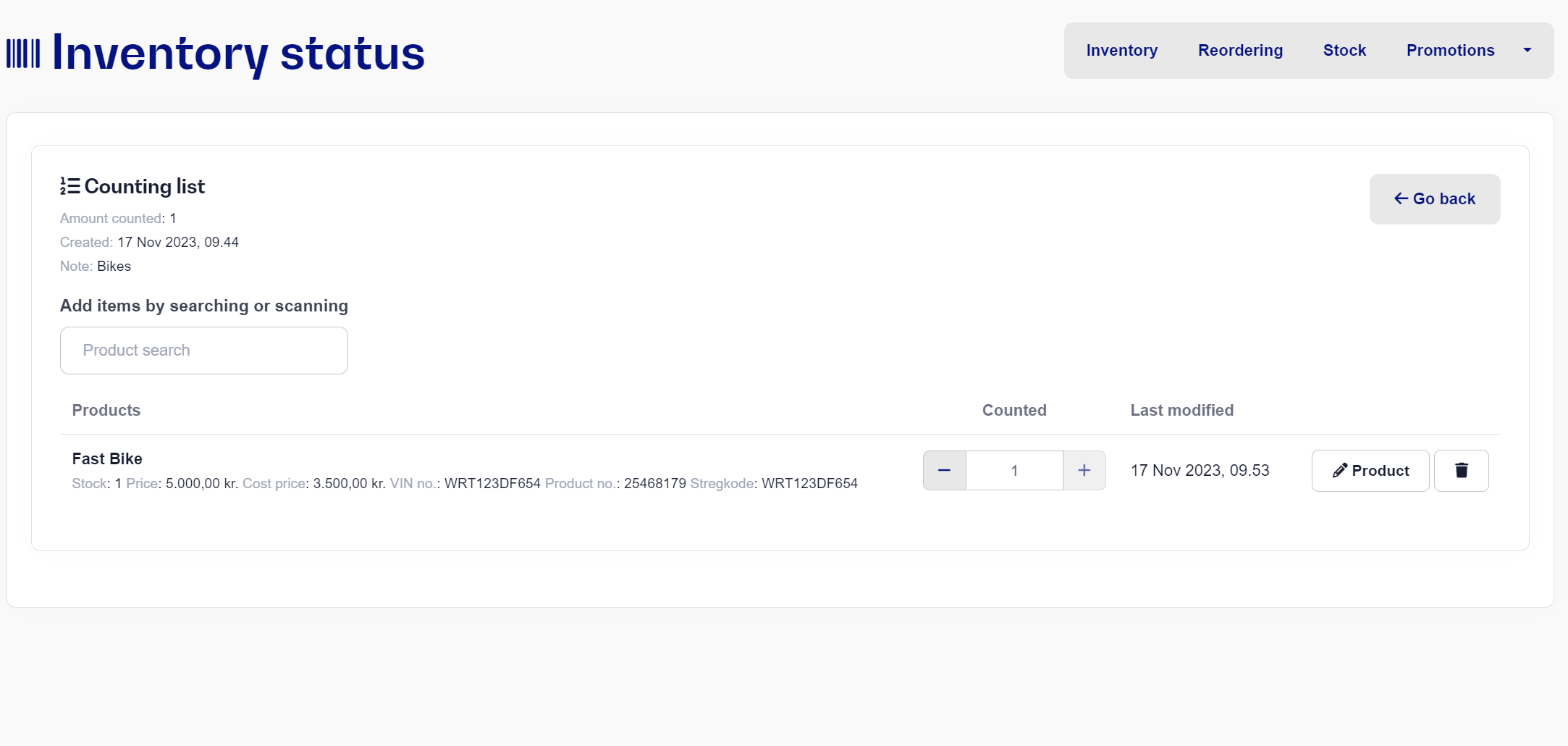

Create as many lists as you would like to make it as easy for yourself to sort your inventory.

As described in the video above, we recommend not conducting inventory receipt adjustments while the inventory is in progress. This is to simplify the inventory as much as possible so that there is no need to account for recently received items. Therefore, try to complete receipt adjustments after the inventory is finished.

Additionally, the following points are important:

Scan an item, enter the quantity, and move on to the next item.

Continue until you are finished in that location.

Go "Back" and select the next inventory list corresponding to the location you are moving to.

Along the way, it can be advantageous for the inventory supervisor to continuously monitor items with discrepancies so that any counting errors can be corrected promptly.

Remember: to count items that are on ongoing work orders. This can be done directly in the workshop or using the "Work Order Materials" report found under Statistics.

Once all areas have been counted, it's time to prepare for the final step.

Completion of Inventory

When completing the inventory, it's time to review your lists for any errors and finalize the inventory correctly.

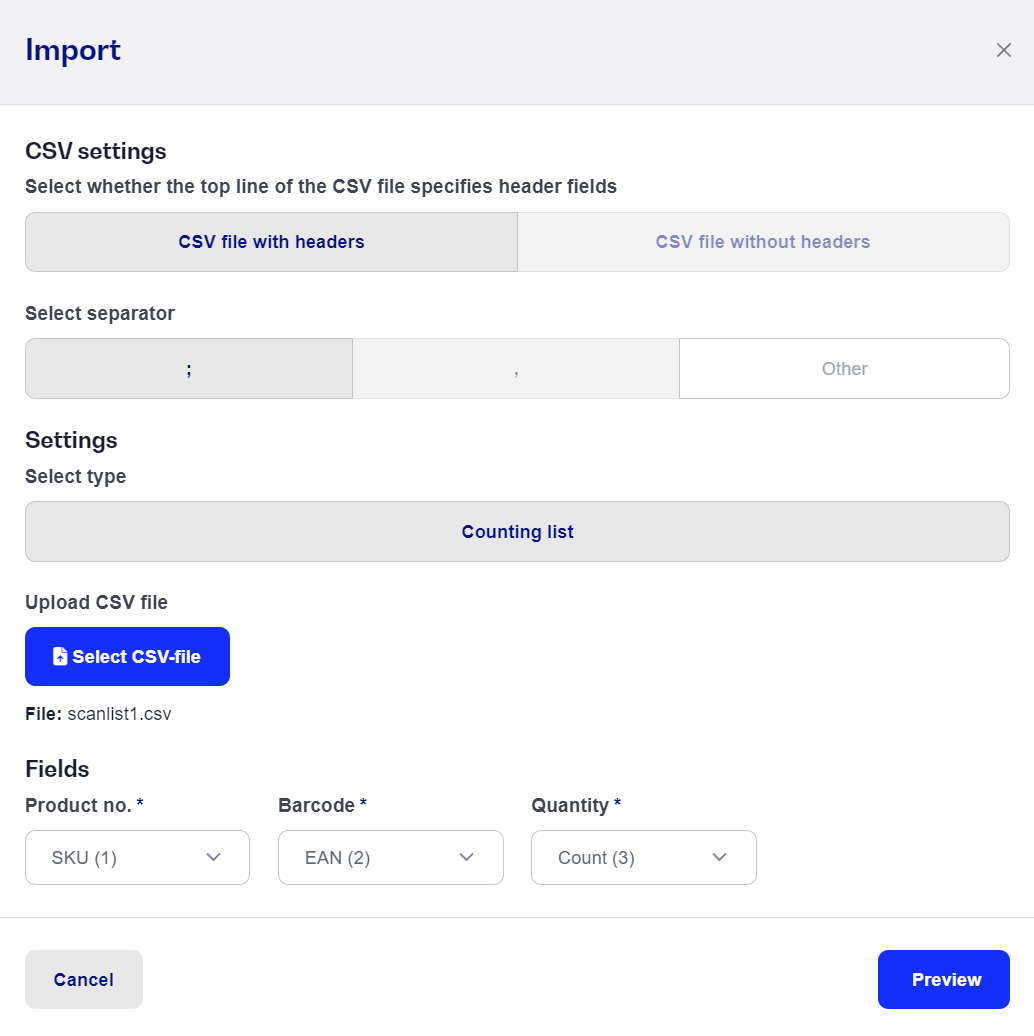

It is also possible to import CSV-files with counted items directly to the stock lists.

This can be useful if you for example are using a handheld status-scanner that saves the counted stock as a file (to a disk or memory card as an excel or CSV-file)

In order for our systsem to process the stock file and improt the changes, it must contain the following data:

Produkt no / SKU

Barcode (EAN/UPC)

Stock count number

The file can then be uploaded though our tool and be added directly into your stock list.

Note: Make sure to select the correct header format, seperator and verify that the file you are trying to upload is an CSV-file encoded in UTF-8 standard.

Example file can be downloaded in the buttom if this article.

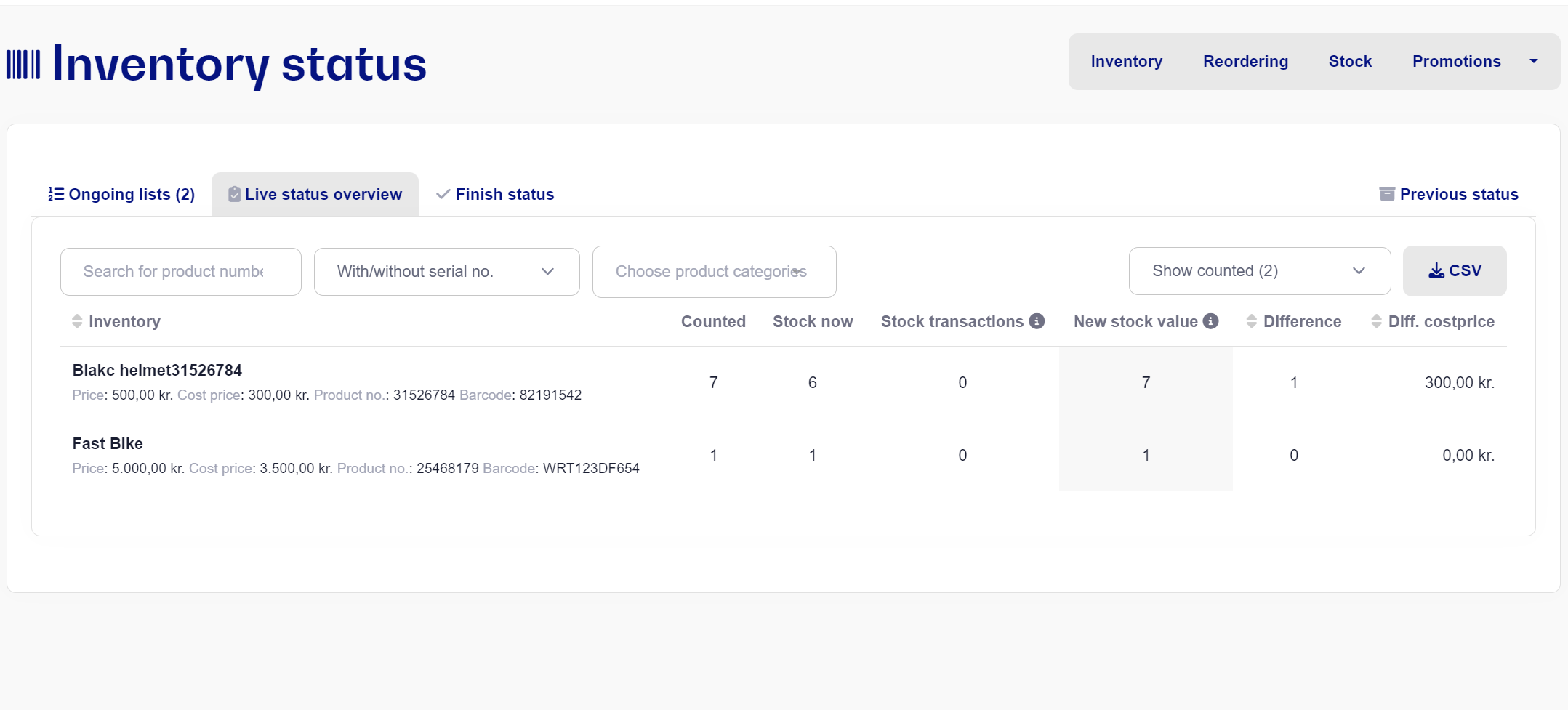

In the inventory overview, you can continually monitor products with discrepancies, as well as see if there are items that have not been counted yet. If you have been keeping track of the inventory overview and which items have discrepancies, the list should be relatively easy to go through, depending on your inventory size.

Video is currently only availible in Danish.

You can sort your overview based on what you want to check - it could be by price, quantity, or product categories.

By downloading the CSV file with discrepancies, you can quickly identify which products need attention. There will almost always be discrepancies in an inventory, but the goal is to identify the discrepancies that are not legitimate. For this, we recommend downloading the CSV file for items with discrepancies and reviewing the areas where these items appear.

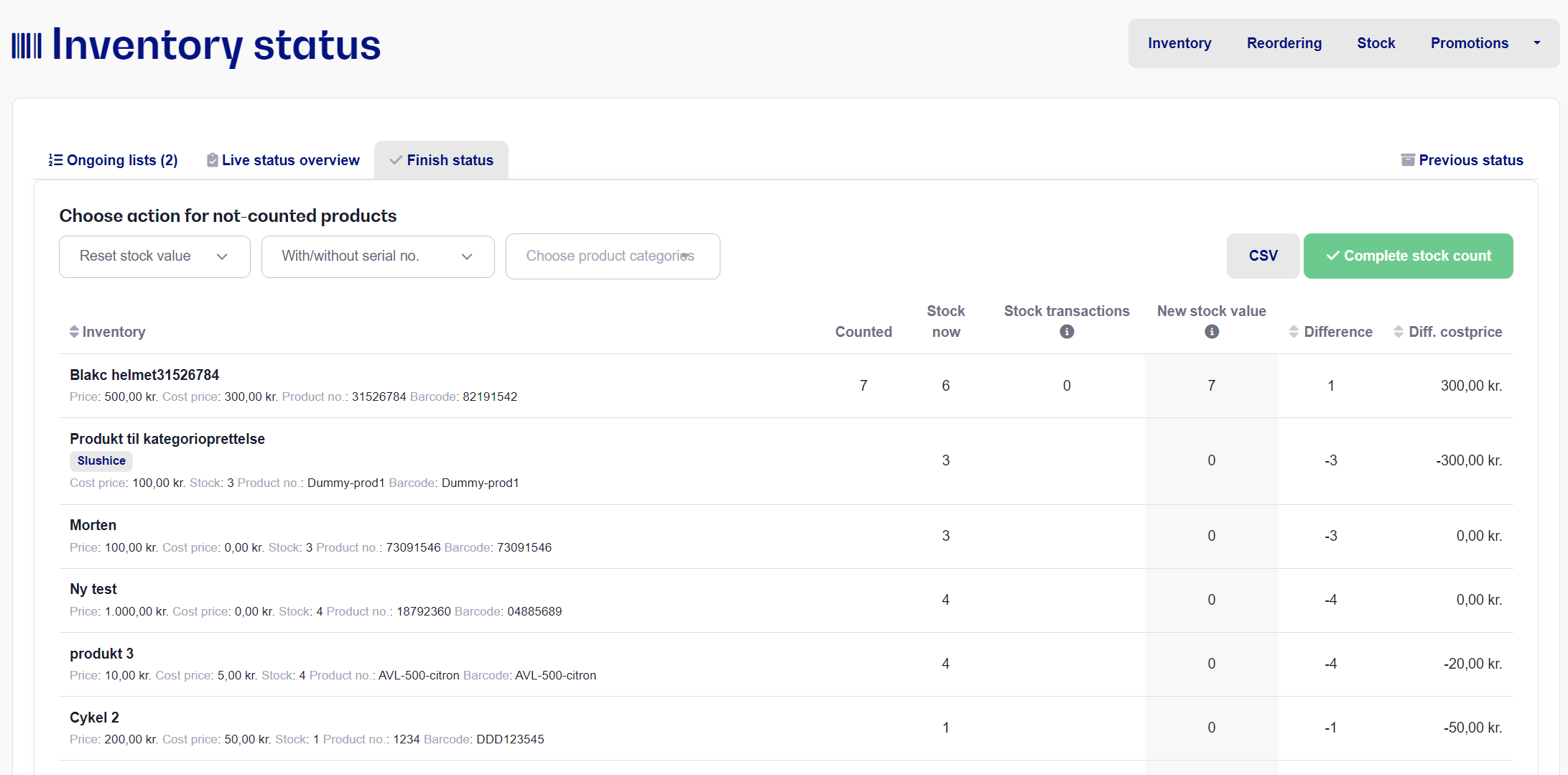

When you reach this point, you will need to make some decisions regarding filters.

What should happen to the items?

Which items should be affected?

Keep current stock count: This choice excludes items that were not counted from the inventory, so the completion of the inventory only affects items that were counted.

Reset Inventory stock: This is the most commonly used option, as it resets the inventory count for items that were not counted. This means that the items that were counted have their inventory values updated to the quantity counted.

With/Without Serial Number: This filter includes all items, regardless of whether they have a serial number or not. If you have performed inventory on the entire inventory, it makes sense to use this filter.

With Serial Number: This option updates only items with a serial number based on the reset filter. This can be useful if you are conducting inventory on items like bikes, electronics, or other items with serial numbers, and you only want to affect these items.

Without Serial Number: This option affects only items without a serial number based on the reset filter. This can be used if you have counted items without serial numbers and want to perform a different inventory specifically for items with serial numbers.

Choose Categories: Here, you can choose to reset only specific product categories. Please note that this choice is based on the filters you have previously set. If you have selected "Reset Inventory Value" and "With Serial Number," it will only affect items with a serial number in the given category.

When you find an item with a discrepancy, you can search for the item under the inventory lists and adjust the quantity as needed, or remove it from the list. As you work through the list, you will see the number of items with discrepancies decrease on the inventory overview.

"Does the status module take into account if an item is already on a counting list and is sold or received via warehouse receipt in Bikedesk (Customers 1st) before the status is completed?"

- Yes. The item is not removed from the counting list and the number of counted items does not change, but in the Status Overview calculation, sales and warehouse receipts made under Warehouse are taken into account.

"Does the status module consider if an item is on a counting list and is manually corrected/made an overwrite before the status is completed?"

- No. Manual changes to inventory should not be made as long as the status is not completed.

"After completing the status, is the inventory number adjusted on my webshop too?"

- When you complete your status, our system sends the inventory changes (also called hooks) to your webshop, just like it would for a normal inventory adjustment.

However, it is not certain that your webshop/host can handle all these changes it receives from our system, so we do not guarantee that the changes will be registered correctly in your webshop if your webshop is not fast enough.

"How do I correct the number of scanned items if I have scanned an item too many or too few times?"

- You can search for the product number under Counting Lists, and the counting list the product is on will appear.

Then you can find the product and correct it by pressing plus or minus on the right side.

If you have many products under a counting list, you can press CTRL + F at the same time - a search field will then appear on the right side of the screen and you can search for the product number.

You can only search one page at a time, so if the item does not appear on the first page, you must go to the next page and search again.

"Can I use my mobile/tablet to scan items with?"

- It is possible to use your tablet/smartphone's camera as a barcode scanner, but this function is still a beta function, so it does not work as well and quickly as if you use a real barcode scanner.

"Can I hold status over several days?"

- Yes, you can. However, we recommend keeping the period as short as possible, as it reduces the risk of errors in counting and makes your troubleshooting much easier.

"Can I receive stock while holding status?"

-Yes, you can. We recommend that you wait until you have completed your status, as it gives you fewer products to keep track of, and therefore reduces the risk of errors.

DISCLAIMER! It is important to note that Bikedesk/Customers 1st cannot take responsibility for any incorrectly counted items.

NOTE: Remember to be aware of adjusting the status/stock changes in your accounting after completion of status/stock count accordingly. We cannot help you with that.